If you’ve ever wanted to create a smooth, level surface for your outdoor space, using a hand tamper for pavers can be a game-changer. With just a few simple steps, we can show you how to achieve professional-looking results right in your own backyard. Whether you’re a seasoned DIY enthusiast or a beginner looking to enhance your outdoor area, mastering the art of using a hand tamper is a skill worth acquiring.

In this guide, we’ll walk you through the basics of using a hand tamper effectively, from preparing the area for tamping to the proper technique for achieving a compacted and stable surface. By following our easy-to-understand instructions, you’ll be able to tackle your paver projects with confidence and precision. Say goodbye to uneven surfaces and hello to a beautifully finished patio, walkway, or driveway with our expert tips on hand tampering for pavers.

Understanding the Purpose of a Hand Tamper

As landscape designers, we know that achieving a professional finish on paver projects requires attention to detail and the right tools. Let’s dive into why using a hand tamper is crucial for ensuring the success of your outdoor endeavors.

The Basics of Tamping

Tamping is the process of compacting the base material, such as gravel or sand, underneath pavers to create a sturdy and stable surface. When we use a hand tamper, we apply downward pressure to eliminate air gaps and ensure that the base is evenly compressed. This action helps prevent future settling and unevenness in your paved area, leading to a longer-lasting and visually appealing outdoor space.

Why Using a Hand Tamper Is Essential for Pavers

When it comes to paver installations, precision is key. A hand tamper allows us to exert manual control over the compaction process, giving us the flexibility to adjust pressure based on the specific area being tamped. Unlike mechanical compactors, a hand tamper enables us to navigate tight corners, edges, and irregular spaces with ease, ensuring uniform compaction throughout the entire project.

Using a hand tamper also provides us with immediate feedback on the level of compaction achieved. By feeling the resistance as we tamp, we can ensure that the base material is adequately compressed, minimizing the risk of future settling. This hands-on approach not only enhances the structural integrity of the paved surface but also allows us to troubleshoot and address any issues in real time.

A hand tamper is not just a tool but a precise instrument that empowers us to elevate our paver projects to professional standards. By understanding the purpose and importance of using a hand tamper, we can take our outdoor spaces from ordinary to extraordinary with confidence and skill.

Selecting the Right Hand Tamper for Your Project

As landscape designers, we know that choosing the appropriate hand tamper for your project is crucial to achieving professional results. Let’s dive into essential considerations when selecting the right hand tamper to enhance your outdoor spaces.

Size and Weight Considerations

When selecting a hand tamper for your paver project, consider the size and weight of the tool. Opt for a tamper that feels comfortable and manageable in your hands. A tamper that is too heavy may cause fatigue and strain during extended use, while one that is too light might not provide enough compaction force. Aim for a balance that allows for efficient compaction without unnecessary exertion.

Materials and Build Quality

Next, focus on the materials and build quality of the hand tamper. Look for a tamper constructed from durable materials like steel or iron, ensuring longevity and reliability in your outdoor projects. A sturdy handle with ergonomic grips can enhance control and reduce hand fatigue, especially during prolonged use. Investing in a well-built hand tamper can make a significant difference in the quality and efficiency of your paving projects.

Preparing the Area for Tamping

Clearing Debris and Ensuring a Level Base

When it comes to preparing the area for tamping, we always start by clearing any debris and ensuring a level base. A clean and level surface is essential for the proper compaction of pavers. Before we begin tamping, we carefully remove any rocks, roots, or other obstructions that could interfere with the process.

To create a solid foundation, we make sure the base is evenly spread and compacted. Uneven or loose bases can lead to poor compaction and uneven paver surfaces. By taking the time to clear debris and level the base, we set the stage for a successful tamping process that results in a smooth and long-lasting outdoor surface.

Adding and Spreading the Paver Base

After clearing the area, the next step is adding and spreading the paver base. We choose a high-quality base material that provides stability and proper drainage for the pavers. It’s important to evenly distribute the base material across the area to ensure uniform compaction.

Using rakes and shovels, we carefully spread the base material to the desired thickness, following the project specifications. A well-distributed base ensures that the weight is evenly supported when tamping, resulting in a sturdy and durable paver surface. By paying attention to these details, we create a strong foundation that enhances the effectiveness of the tamping process.

Step-by-Step Guide: How to Use a Hand Tamper for Pavers

The Proper Stance and Technique

When using a hand tamper for pavers, we emphasize the importance of adopting the correct stance and technique to achieve optimal results. Stand with your feet shoulder-width apart and position the tamper vertically on the paver surface. Keep your back straight, bend your knees slightly, and apply firm but controlled pressure on the tamper. Engage your core muscles to maintain stability and focus on exerting force downward rather than forward. This technique ensures effective compaction without straining your back or shoulders.

Tamping in Sections for Uniform Compaction

To ensure uniform compaction across the entire paver surface, we recommend tamping in sections. Divide the area into manageable parts and work on one section at a time. Start from the outer edges and move towards the center, overlapping each tamp to integrate the compaction seamlessly. Apply consistent pressure throughout each section to prevent uneven compaction and achieve a smooth, level surface. Tamping in sections allows for better control and even distribution of compaction, resulting in a sturdy and durable paved area.

Safety Tips While Using a Hand Tamper

Safety is paramount when using a hand tamper for pavers. We advise wearing protective gear such as work gloves, safety glasses, and sturdy footwear to prevent injuries. Ensure that the work area is clear of debris and obstacles to avoid tripping hazards. Lift the tamper using your legs, not your back, to prevent strain. Take regular breaks to rest and hydrate, especially when working on large projects. By following these safety tips, we can prioritize our well-being while achieving professional results in our paver projects.

Finishing Touches After Tamping

Checking for Evenness and Making Adjustments

Once the tamping process is complete, we need to ensure that the surface is level and even. To do this, we recommend using a straight board or a level to check the surface of the compacted pavers. Placing the board across the newly tamped area and checking for any gaps or uneven spots will help us identify areas that may need additional compaction.

If we find any low or sunken areas, we can add more paver base material to those spots, then re-tamp the area to achieve a uniform surface. It’s essential to pay attention to these details to guarantee a beautifully finished paver project that not only looks great but also functions effectively.

« Unveiling the Ultimate Secrets to Patio Paver Perfection: Your Definitive Guide to Maintenance Magic Uncover the Ultimate Secrets to Stunning Pavers with Lush Turf – A Landscaping Dream Come True »

Adding Sand and Laying Pavers

After achieving a smooth and level surface with the hand tamper, the next step is to add a layer of sand to create the bedding for the pavers. Spread a thin, even layer of sand over the compacted area and use a straight board to screed the sand to an even thickness.

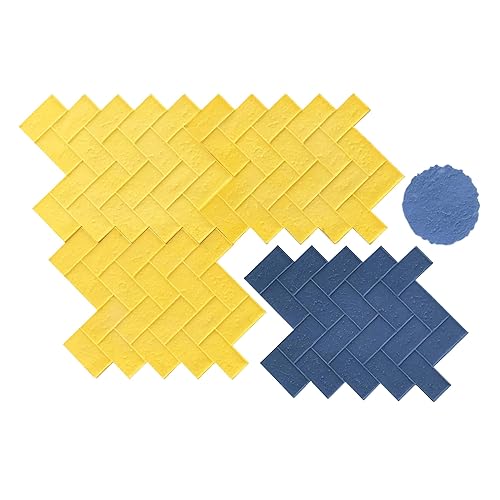

Once the sand is in place, it’s time to lay the pavers according to the desired pattern. Start laying the pavers from one corner and work your way across the area, ensuring that each paver is snug against its neighbor. Use a rubber mallet to gently tap the pavers into place and maintain a consistent level.

As we continue to lay the pavers, periodically check for levelness and alignment, making any necessary adjustments along the way. Taking the time to lay the pavers correctly will ensure a professional-looking finish that will stand the test of time.

Maintenance and Care for Your Hand Tamper

As landscape designers, we understand the importance of maintaining and caring for our tools, including hand tampers, to ensure they stay in top condition for our paver projects. Proper maintenance not only extends the tool’s lifespan but also enhances its performance, leading to better results in our outdoor surface endeavors.

Cleaning After Use

After completing our paver project and the final tamping process, it’s crucial to clean our hand tamper to remove any dirt, debris, or residual materials that may affect its functionality. Here’s how we can effectively clean our hand tamper:

- Wipe Down: We should start by wiping down the tamper’s surface with a damp cloth to remove any loose particles or soil.

- Brush Off: Using a brush, we can gently scrub the tamper to dislodge any stubborn dirt or debris stuck on its base.

- Dry Thoroughly: Once cleaned, we need to ensure the hand tamper is thoroughly dried to prevent rust or corrosion.

Regular cleaning after each use keeps our hand tamper in optimal condition for future projects, ensuring smooth and efficient compaction.

Storage and Handling Tips

Proper storage and handling practices are essential to safeguard our hand tamper and maintain its quality. Here are some tips on how we can store and handle our hand tamper correctly:

- Cover or Store Indoors: To protect our hand tamper from environmental elements, it’s advisable to store it indoors or cover it with a tarp when not in use.

- Avoid Moisture: Moisture can lead to rust, so we should store our tamper in a dry area to prevent any water damage.

- Store Vertically: Storing the hand tamper vertically helps prevent warping or bending of the base plate, ensuring uniform compaction during future use.

- Regular Inspection: Periodically inspecting our hand tamper for any signs of wear and tear allows us to address any issues promptly and maintain its effectiveness.

By following these cleaning, storage, and handling tips, we can prolong the life of our hand tamper and continue to achieve professional results in our paver projects.

Conclusion

Mastering the art of using a hand tamper for pavers is key to achieving a flawless outdoor surface. From selecting the right tamper to maintaining it for longevity, we’ve covered it all. Remember, proper technique and attention to detail are crucial for uniform compaction. Ensuring evenness, laying pavers correctly, and maintaining alignment are essential steps for a professional finish. By following our tips on post-tamping adjustments and sand bedding, you’ll be well on your way to a successful paver project. Don’t forget to care for your hand tamper by cleaning it after use and storing it properly. With these insights, you’re ready to tackle your next paver project with confidence!